Technology

ECORBIT proposes the environmental

technologies of tomorrow

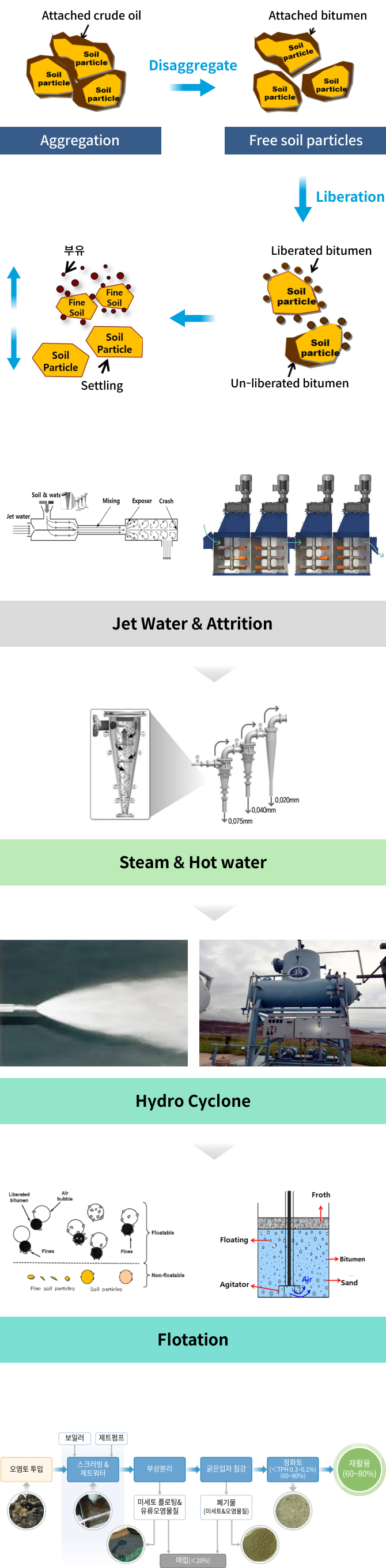

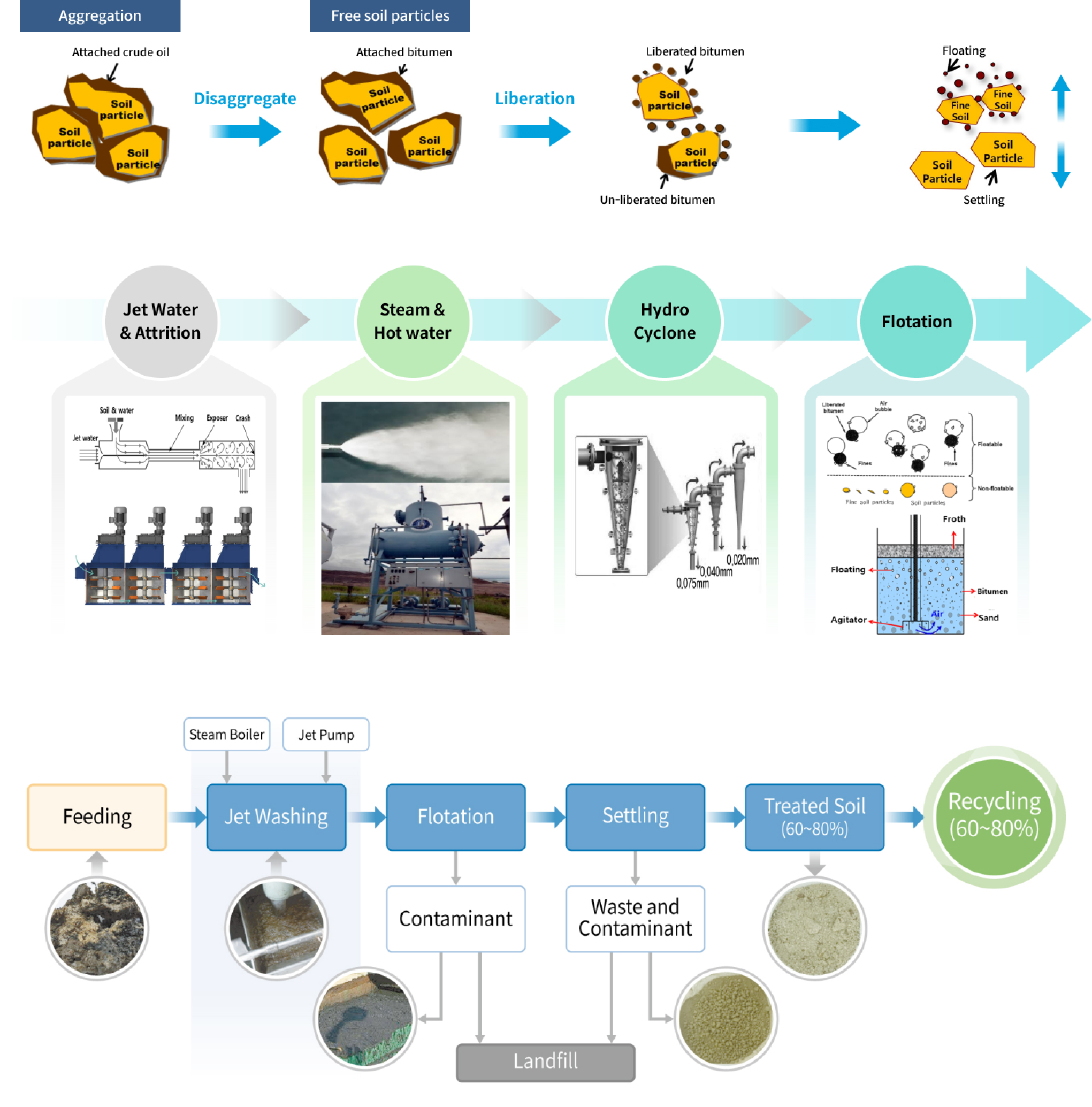

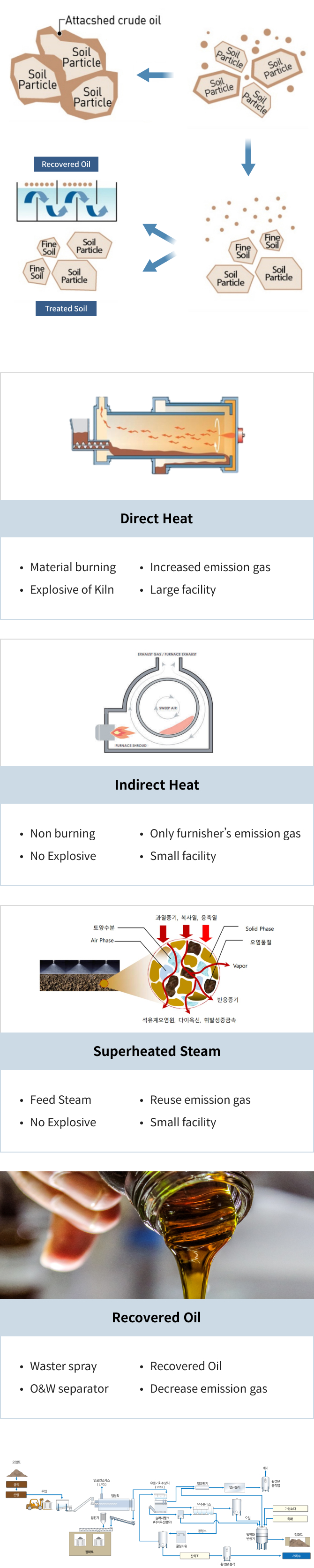

Soil Washing :

Jet & Nanobubble

Washing Method

Soil Washing

Jet Water

Soil Washing

Jet WaterWater Jet Washing Process is used the shock energy generated in the process of crushing the cavitation bubbles and high pressure water jet through the customs tube to liveration and remove pollutants pressent on the soil surface. It can be a technology that can reduce the amount of medicine used. After liberation process, fine treated soil and contaminated soil with oil should separated in next process to protect the increasing of landfill operation volume by filter cake. So in this process should operate multi hydro cyclone for recovery fine treated soil and other waste material, contaminant with oil/metals should folate to tank surface to skimming.

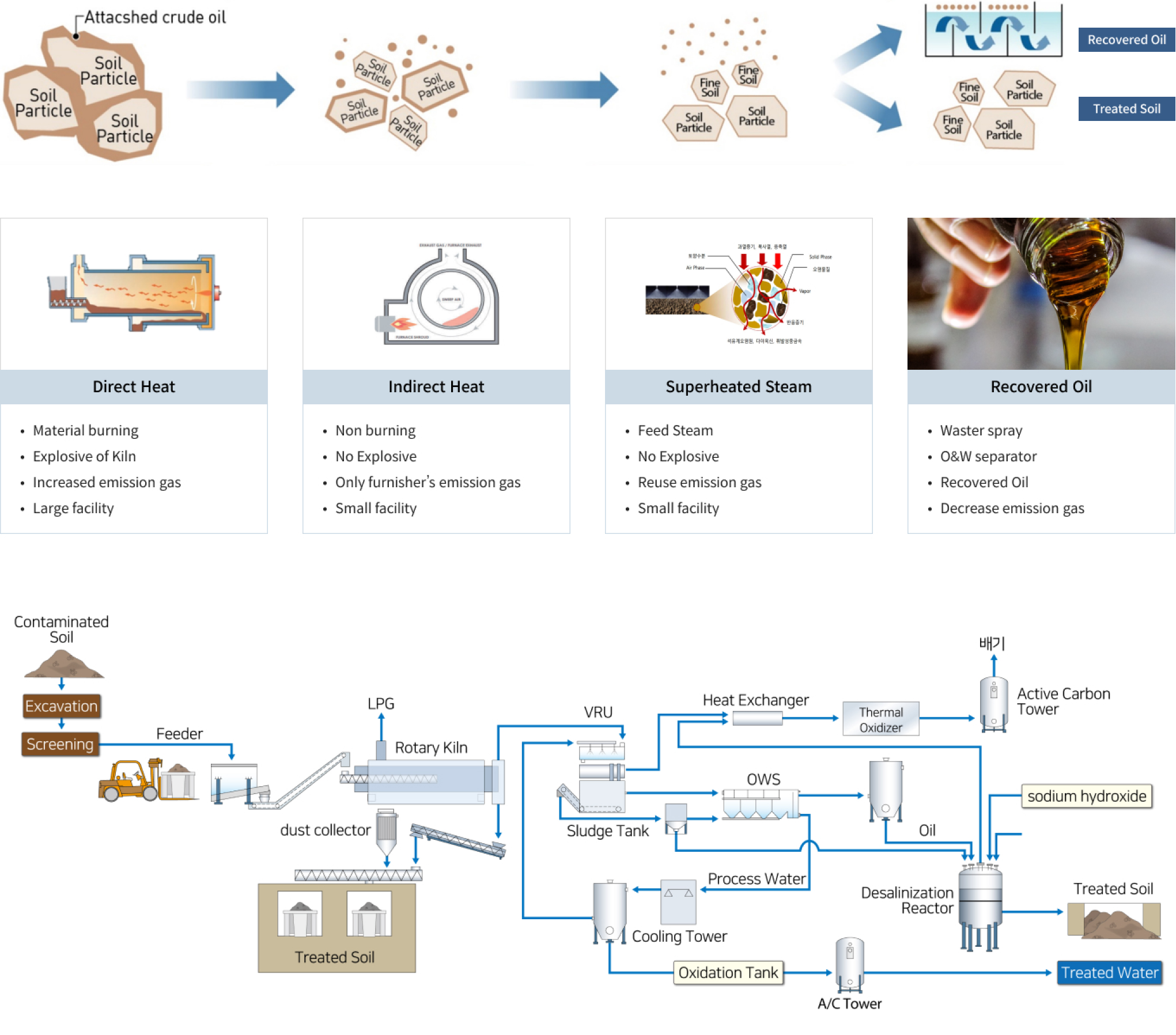

Low Temperature

thermal Desorption

(LTD, Indirect and Superheated steam)

Low Temperature

thermal desorption

Low Temperature

thermal desorption

We have technology to purify high concentration contaminated soil contaminated with crude oil. The direct thermal desorption method applies indirect thermal desorption to VOC evaporation and prevents self ignition by controlling the O2 content in order to solve the problem of controlling internal combustion by self combustion when high concentration contaminated soil is injected. In addition, it can increase the thermal efficiency of the kiln through a multi burner and has a technology of superheated steam method to evaporate pollutants through heat transfer (convection, conduction, radiation) in direct contact with pollutants.

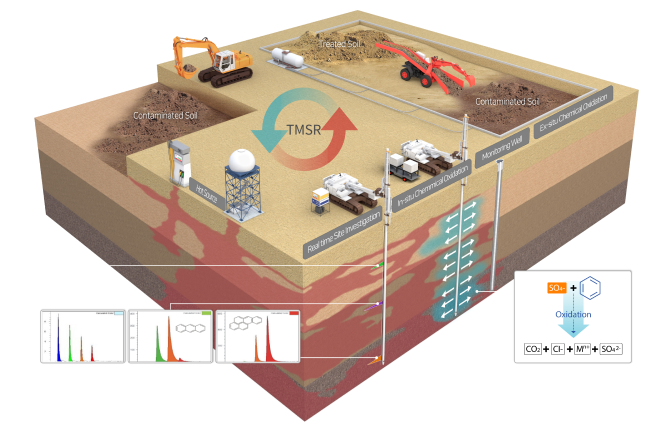

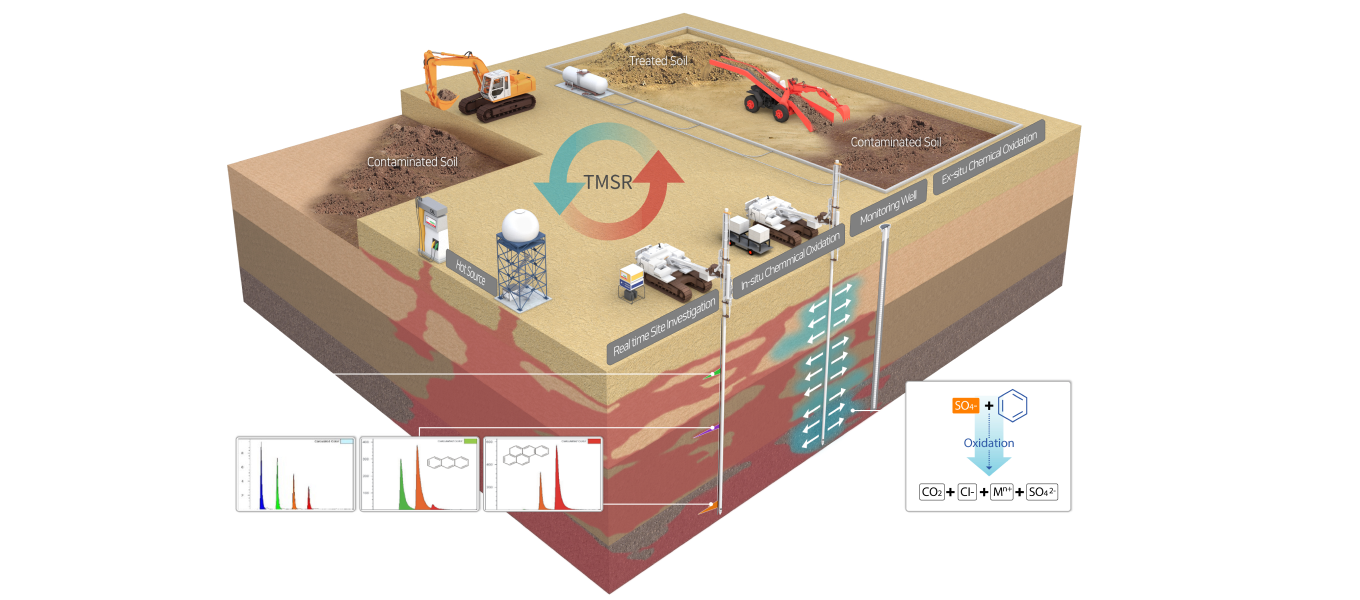

Total Management

System of

Soil Remediation

Total Management System of Soil Remediation)

Total Management

System of

Soil Remediation

Total Management System of Soil Remediation)

TMSR is new technology that it use the real time site investigation and remediation technology for applying the In situ Chemical Remediation. TMSR technology of ECORBIT can do a real time monitoring, decrease uncertainty of site survey, correct contaminated map of underground, efficiency decision making and increase remediation efficiency.

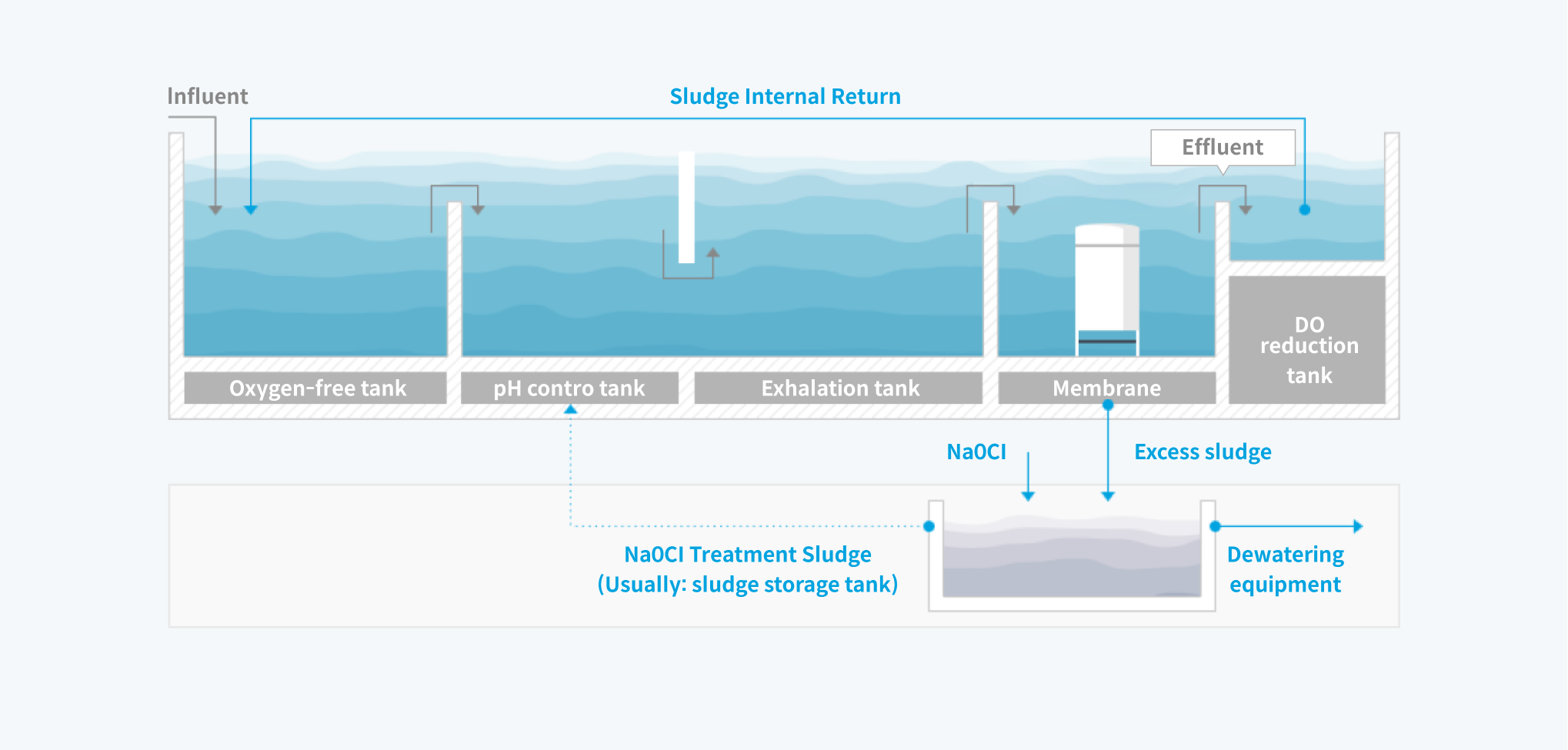

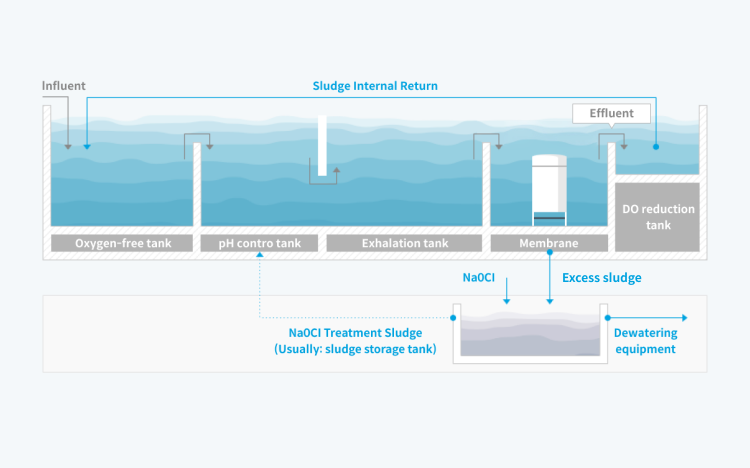

Advanced wastewater

treatment technology

- 1

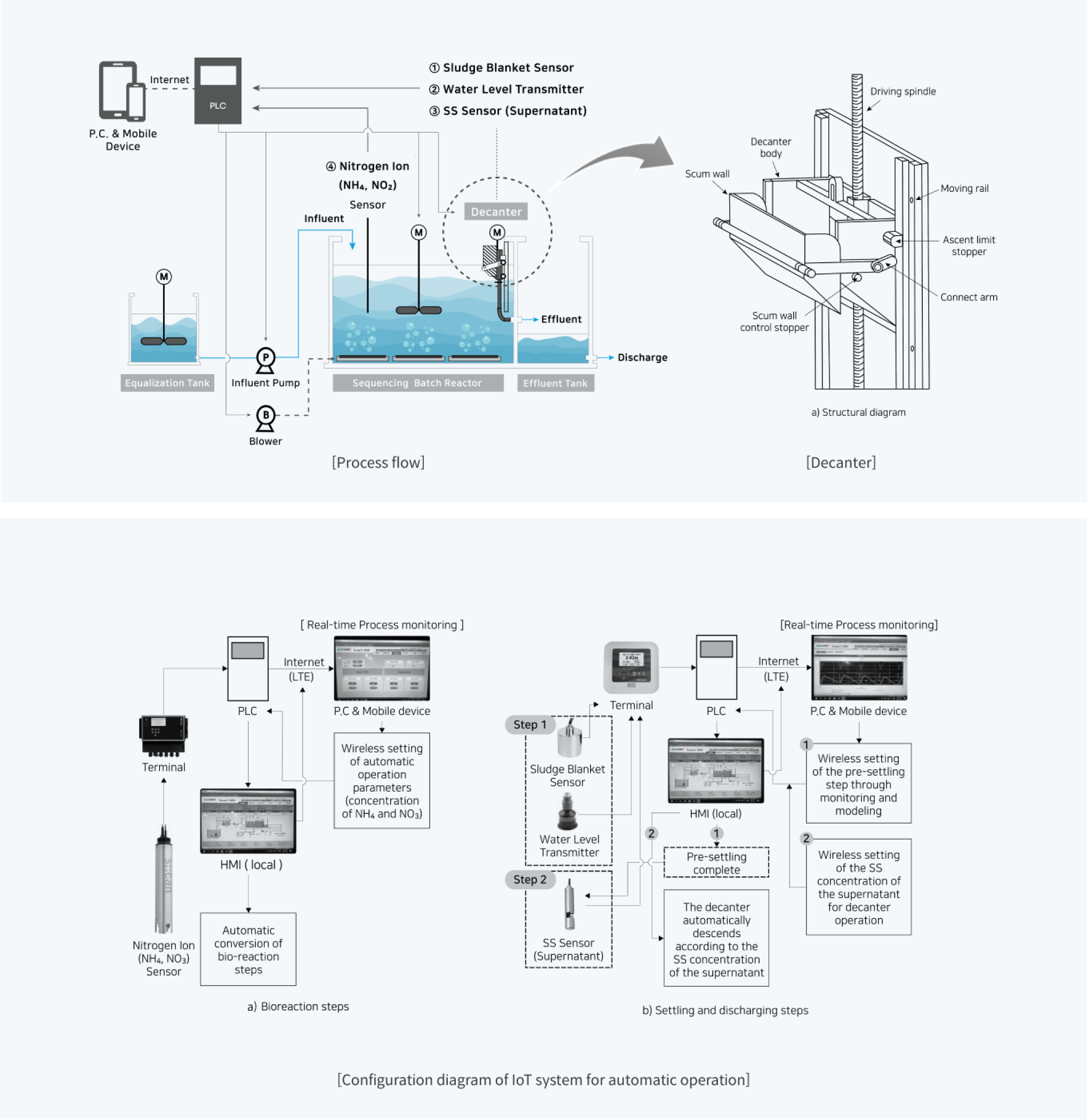

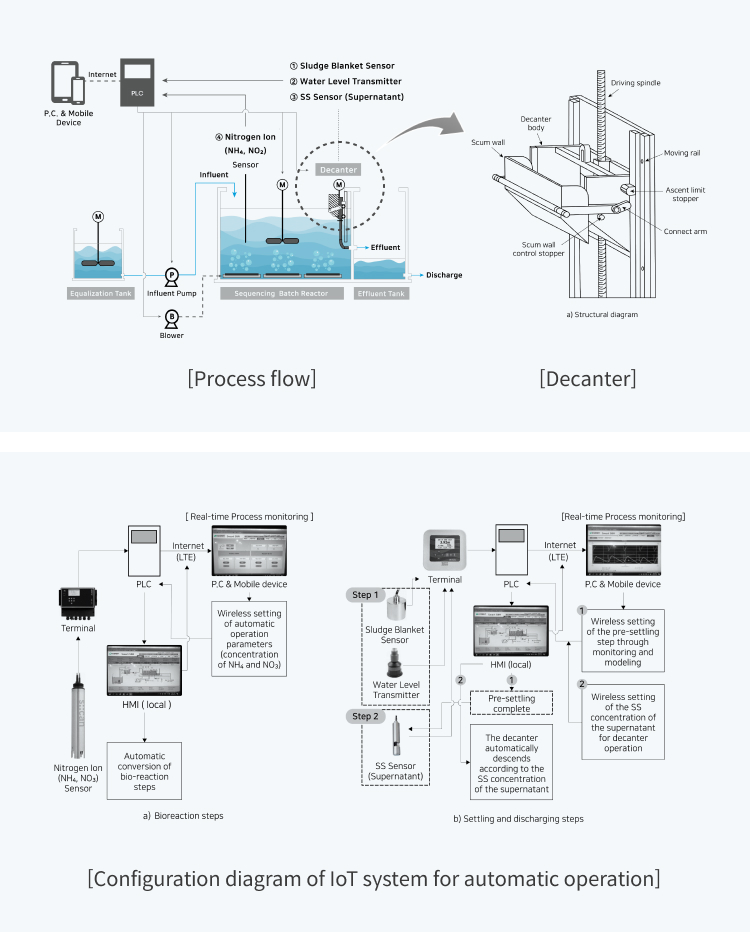

- Real-time process modeling based on influent water quality monitoring (AHRT optimal control)

- 2

-

Automatic control of the anoxic-aerobic steps according to

the behavior of nitrogen ions in the bioreactor

- 3

-

Automatic control of the decanter according to the settling

characteristics of the activated sludge reduces the time required

for the settling discharge step by 50%

Treatment Technology

- 1

-

Manufacture NaOCl

treated sludge using excess sludge and

inject it into a bioreactor

- 2

- Increasing microbial activity by supplying carbon source and alkalinity

- 3

- Optimization of nitrogen and phosphorus removal efficiency

approximately 4%

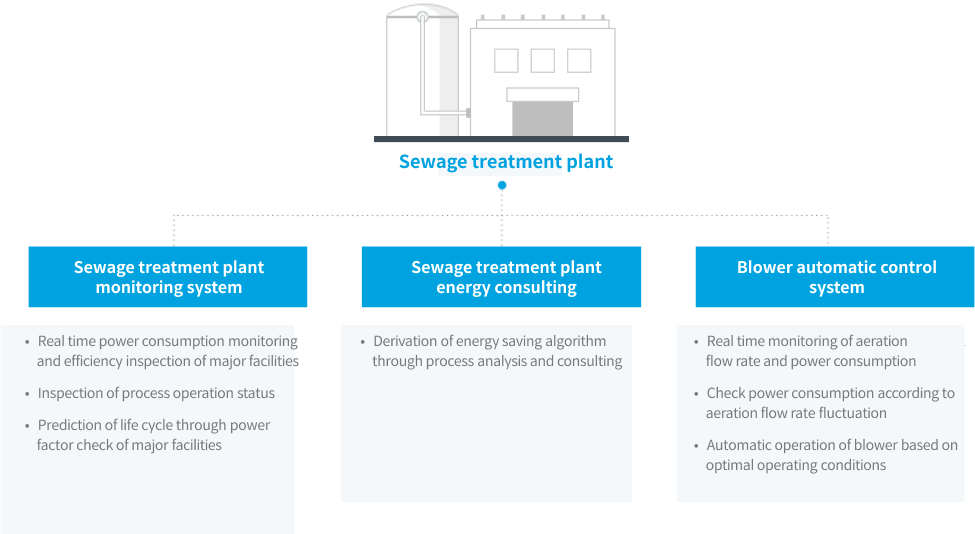

which account for 40% of the sewage treatment plant. Possible to reduce blower power used in sewage treatment plant by

more than 10% → Reduce overall sewage treatment plant power by 4%

- 1

- Sewage treatment plant monitoring system Power consumption measurement / Operating factor analysis

- 2

- Analysis and consulting for sewage treatment plant energy use Analyzing operating data and predicting aeration reduction

- 3

- Build a blower automatic control system Algorithm through 1 and 2 steps / Applying blower energy saving control system

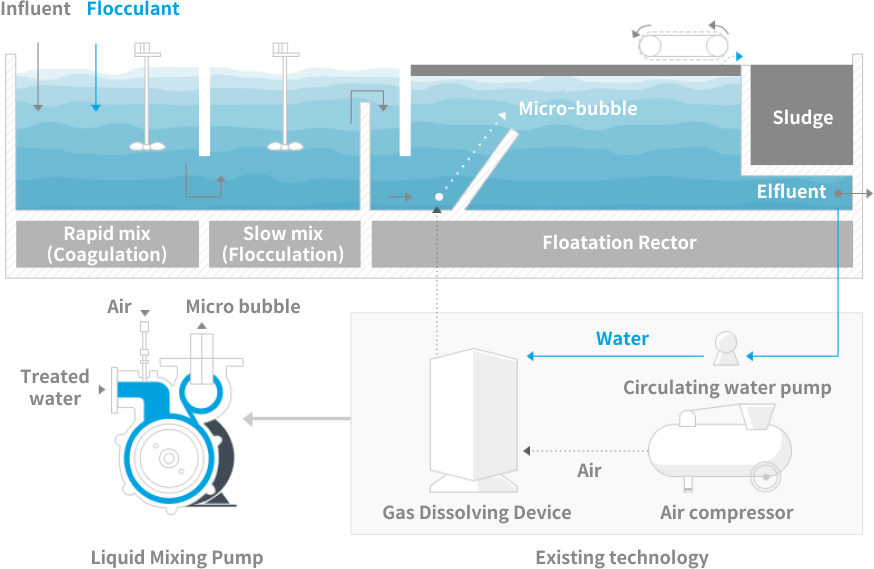

nozzle

- Semi permanent material, no need to replace

- On-site custom fine adjustment is possible

- Increased contact area by spraying in two places

mixing pump

- 30~40% reduction in power consumption compared to existing technologies

- Excellent maintainability by minimizing facilities

- Foot print reduced by at least 50% compared to existing technology